What Does Central Park have to do with Export Packaging?

If you’ve ever strolled down the main thoroughfares of New York City’s magnificent Central Park, then you likely remember the canopy of leaves that forms a beautiful cathedral-like ceiling above you. Huge, stately trees are what Central Park is all about; without them the park just wouldn’t be the same.

But those trees are threatened, and that threat has everything to do with…well, export packaging.

What could we possibly be talking about?

Many of those towering trees in Central Park are American elms. Elms were used extensively in public parks and thoroughfares throughout the eastern United States in the late 1800s and early 1900s. But then something happened. A shipment of wood from overseas brought something unexpected: a new disease, which had been identified by a Dutch scientist and so named Dutch Elm Disease.

The rest is history. After landing in New York City in 1928, Dutch Elm Disease swept the continent, killing millions of trees. Researchers estimate that Dutch Elm Disease killed approximately 75% of the 77 million elms in North America between the years of 1928 and 1989. Only in the last decades have scientists found effective ways of fighting the disease, and it still regularly threatens the stately elms in Central Park, where more are lost each year. It’s a sad story, especially if you’ve ever seen the way that a diseased tree so quickly bites the dust.

But this isn’t actually a story about elms. It’s an article about Export Packaging.

My detour through Central Park serves to underline the point that I want to make here:

Bugs—like other invasive species—are a huge concern in global economies. Someone fells a tree halfway across the world, sends the lumber to New York and all of a sudden thousands, then millions of trees are dying. In order to combat the spread of bugs and fungi we now have very specific standards from the ISPM (International Standards For Phytosanitary Measures) about how to treat wood so that it is safe to send around the world.

But wait. You’re not sending wood to Africa, are you. So what does this have to do with YOU?

Well, even if you’re not exporting wood, your shipment might be packaged or crated using wood. That’s where we come in. In order to guarantee the smooth shipment of machinery, parts, or products overseas, you need to work with a crating company that has extensive experience with export packaging and can fully comply with the ISPM standards.

Meeting the ISPM-15 Standards

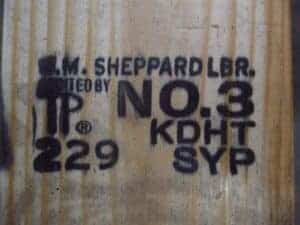

The most recent ISPM-15 standards apply to any wood material that is thicker than 6mm—including pallets, crates and dunnages. All wood must be heated until its core reaches 56 °C (133 °F) for 30 minutes. Please don’t do this at home. Export packagers like us use wood that is heat treated at the mill and certified to be ISPM compliant. For all export packaging jobs, we use only certified wood. The certified wood comes with a special stamp (like the one shown at left) that shows it meets the regulations.

After cutting the wood up to construct export crates, the original stamp may no longer show, so we put our own stamp on it—called the “bug stamp” or the “wheat stamp” in the industry. Shown at right, this stamp communicates to control agencies that the packaging is safe for international travel and meets the ISPM-15 standards.

Don’t Risk It

Without the ISPM-15 stamp, there’s a long list of pretty horrible things that could happen to your shipment. Often the packaging is destroyed and re-packaged at a premium rate (charged to you, of course). But we’ve even heard about control agencies that send the entire shipment back to the sender, at the sender’s cost. Don’t risk it!

And besides, it’s these export packaging rules that help to ensure that the towering elms of Central Park stay alive and well for decades, even centuries to come.

Give us a call today to discuss your export packaging job.